Revolutionize your Field Service Management

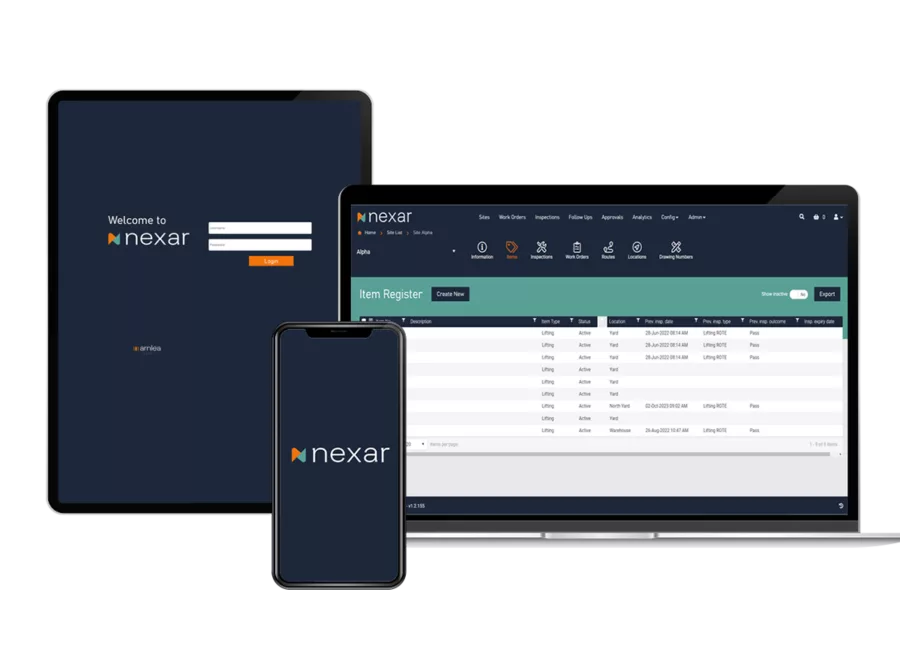

From inspections and maintenance to materials and logistics, operations become seamless as our software, Nexar connects all your data from the field to the office in real-time.

Integrating seamlessly into your corporate ecosystem and by using the latest handheld, fixed reader, RFID, and barcode technology, Nexar gives you a centrally managed solution that saves time, improves data accuracy, and optimizes staff safety and operations.

Say goodbye to unproductive, timely, and costly processes and hello to….

Safety and Security

The biggest concerns for our customers revolve around compliance and trust. Arnlea invests in industry recognised security and systems, underpinned by global standards and accreditations, to instill confidence that your data is always secure.

Inspections & Maintenance

The answer to your inspection and maintenance challenges.

Nexar allows you to inspect, report and analyse inspections with ease. And, by integrating into your corporate ecosystem, Nexar gives you one centrally managed solution that reduces repetitive admin tasks, saves time, and improves data accuracy. Freeing our clients to focus on their core operations.

Supply Chain & Logistics

The answer to your supply chain and logistic challenges.

As a centrally managed solution, Nexar gives you greater visibility across your whole supply chain network. Office staff receives real-time data that allows smarter, more informed decisions to be made, and on-site staff can carry out operations in the field with the touch of a button.

Sustainability

Arnlea recognizes that we need to play our part when it comes to sustainability and make a positive difference. We want to help our clients reach their targets too, which is why Nexar has been built with sustainability in mind.

Firstly, as a mobile, cloud-based app, CO2 emissions are reduced by 50%, compared to an on-premise server. Secondly, as manual processes are eliminated, and fewer people are required in the field, businesses benefit from reduced energy costs and carbon footprint.

Operational efficiencies go up, and environmental burdens go down – making your business future-proof.

Arnlea has strong relationships with some of the biggest brands in the Energy sector

What our clients say

Arnlea were excellent at assisting us in solving many problems at a granular level, understanding our needs and enabling a smooth data migration onto the Nexar platform. We then had a solid basis to move forwards in establishing consistent and accurate CompEx data across the plant, enabling our inspectors to successfully resolve many issues and dramatically improve the quality and accuracy of reporting to the client and safety monitoring.

We find that the app gathers all the data well and custom reports enable us to present professionally to the client. Back office management of the site in Nexar is very straightforward.

Arnlea also gave us very effective help in learning Nexar and deploying it in the field. We are very pleased with the high standard of support we’ve received.

James Bottomley

IT Manager

“The contribution that Arnlea's software has made to our inspection teams and technical analysis has been invaluable. The high service levels we receive from all at Arnlea made this contract renewal straightforward and the next logical step.”

Steven McDuff

ECI LEAD

Arnlea’s team has been supportive and instructive throughout the upgrade and we’re benefiting from reducing the number of inspectors on site, while increasing the number of inspections we perform. We’re able to obtain inspection data a week earlier than before and that data is at least 50% more accurate than when it was manually. We estimate cost savings to be around £350k per annum.

Dave

VERMILION